Frey has the knowledge, capabilities, resources and personnel to deliver outstanding industrial projects. Our experience stretches across all phases of a project, from pre-construction to completion, including commissioning and start-up.

Frey has served the Industrial market for almost 50 years, applying our mechanical, civil, electrical and structural expertise to provide tailored, turnkey solutions.

Through our integrated and collaborative approach we work in partnership with our clients to address the unique challenges and opportunities inherent in each individual project. By providing single source services we can help increase efficiency, and maximize results by streamlining the delivery process. Frey provides the expertise and resources needed to manage entire building projects, from design to ribbon cutting.

Regardless of the scope of work, we are sensitive to budgetary constraints required to make projects an ongoing success. We understand and are committed to meeting completion schedules, and staying within budget in order to successfully deliver new builds and renovated projects to owners.

Our industrial design-build and general contracting expertise includes:

MANUFACTURING • FEED MILLS • FACTORIES • CHEMICAL • ENERGY • ADDITIONS & RENOVATIONS

industrial PROJECTS

PROJECT PROFILEs

Jones Feed Mill

Project: Jones Feed Mill

Location: Linwood, Ontario

Sector: Industrial

Construction Type: Fixed

PROJECT OVERVIEW

Located in Linwood, ON, Jones Feed Mill has been in business since 1930 and continues to grow by providing superior service. Jones contracted Frey Building Contractors to build a new 172’ tall pellet mill alongside their existing successful feed mill. Jones Feed has a variety of companies under one umbrella offering feed to an abundance of different livestock including: equine, beef, dairy, poultry, sheep including an Organic specialty feed program. Jones Feed produces over 200,000 tonnes of feed each year to local farms across Ontario as well as shipping overseas around the world.

Not only does Jones Feed Mill provide food to livestock, they also provide food to feed us all including pork from their very own Black Creek farms and cereal from their Nith River Milling location.

AMI Attachments

Project: 51,280 sf Manufacturing Plant and Offices

Location: Region of Waterloo, Ontario

Sector: Industrial

Contract Type: Construction Management

PROJECT OVERVIEW:

AMI Attachments is an industry leading North American manufacturer of heavy construction equipment. AMI selected Frey Building Contractors to construct its new manufacturing facility, and offices. This project was delivered under a construction management contract. The facility combines AMI’s North American manufacturing operations with AMI’s North American head office. The manufacturing plant is designed and built to handle and manufacture heavy equipment, and includes multiple overhead cranes, a paint booth and wash bay. An epoxy coating on the concrete floor creates a clean, professional appearance to the manufacturing area. Change facilities with showers are located in the basement. The building placement on the property emphasizes the beautiful 2 storey office building, which is clad in a glass curtain wall, and accented with stucco. The entry opens up to a 2 storey atrium with a mezzanine, and is filled with natural light. The atrium features a staircase with glass balustrades and stainless steel railings. An interior stone feature wall accents the modern, classy look of the entryway. The office area includes a kitchen and dining room.

Wallenstein Feed & Supply Ltd.

Project: Mill 4

Location: Wallenstein, Ontario

Sector: Industrial

Contract Type: Fixed Price

PROJECT OVERVIEW:

For almost 60 years Wallenstein Feed & Supply (WFS) has been manufacturing quality feed for the Ontario livestock industry. WFS is a valued, repeat client of Frey Building Contractors since 1998.

WFS selected Frey for the structural construction of Mill 4, an impressive state-of-the art facility. WFS is the largest independent, family owned livestock feed mill in Canada and runs 24 / 6. The official opening ceremony and open house for Mill 4 was attended by 2,000 people. The volume of production requires 100 trucks coming in and out every day.

The construction statistics for Mill 4 speak to the size and complexity of the project:

87,000 metric tonnes of granular materials

Contract documents totaling 4,450 linear feet of paper

A 14,000 square foot warehouse with a robotic palletizer and 800 racking spaces

Interior inbound and outbound truck weigh scales

A 26 foot deep basement

Building height of 130 feet from the ground, and 170 feet to top of the elevator discharge

3,843 meters of concrete

262. 56 tons of rebar

708.1 tons of structural steel

72,238.5 millwright man-hours

65,000 Frey labour hours

18 miles of welding rods

244 kilometers of electrical wire

102 doors

487 electric motors totaling 5,098 connected horsepower

Elmira pet products

Project: 55,100 sq.ft Manufacturing Facility Addition

Location: Elmira, Ontario

Sector: Industrial

Contract Type: Construction Management

PROJECT OVERVIEW:

Elmira Pet Products is the largest Canadian private label dry pet food manufacturer, with a history dating back to 1923. In recent years they have invested $27,000,000 in equipment and infrastructure, including a major expansion to their mixing plant, production, packaging and office areas. Elmira Pet Products selected Frey Building Contractors as the Construction Manager for this major addition. The addition included new production lines, packaging area and a 2 storey office. Some of the features of this challenging and complex project include; specialized mechanical and production equipment, waste water treatment, fire reservoir and cold receiving docks. A welfare area is incorporated into the 2 storey office addition, and includes a lunchroom and training rooms. Frey delivered this project on time and on budget, despite a tight schedule, project complexity and numerous changes made during the project.

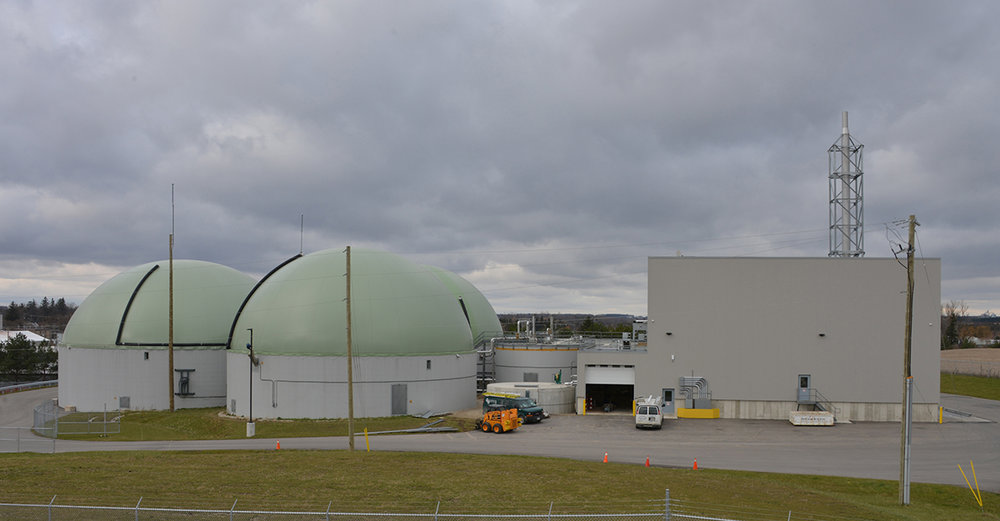

WOOLWICH BIO-EN

Project: Biogas Energy Plant

Location: Elmira, Ontario

Sector: Industrial

Contract Type: Hybrid T & M, Fixed Price and Construction Management

PROJECT OVERVIEW:

Woolwich Bio-En produces green, low cost, renewable energy from the anaerobic digestion of organic waste. Frey Building Contractors was selected to construct this 2.85 Megawatt biogas energy plant. Through a process of fermenting biomass and other garbage, the plant produces methane gas which is used to generate electricity and usable heat. This project was delivered with a combination of Time and Material, Fixed Price and Construction Management contracts. The scope of work also included providing working drawings. The technology for the plant is European, and Frey was tasked with sourcing materials and methods that could be acquired locally. Of particular concern was the material used to construct the digester tank and treatment tanks, because the environment in the tanks is extremely corrosive. The components of this construction project included; heat and power building, process building, pre-treatment tanks, digesters, repository tank, truck filling pump house, fire reservoir and truck scale. The plant processes 70,000 tonnes of organic waste per year, and operates 24 hours a day with only 5 employees.

“Our firm has worked with Frey’s for over 25 years. We consider Frey to be a contractor of choice for their high quality of workmanship, their dependability and their distinguished ethical standards. Several projects with Frey have been high quality agricultural facilities. Additionally our experience with Frey’s includes large industrial and commercial projects, which demonstrates the broad experience and capabilities of their company. Overall, we find the management, in-house design staff and site personnel of Frey Building Contractors to be a pleasure to work with, and we are proud of our association with their firm.”